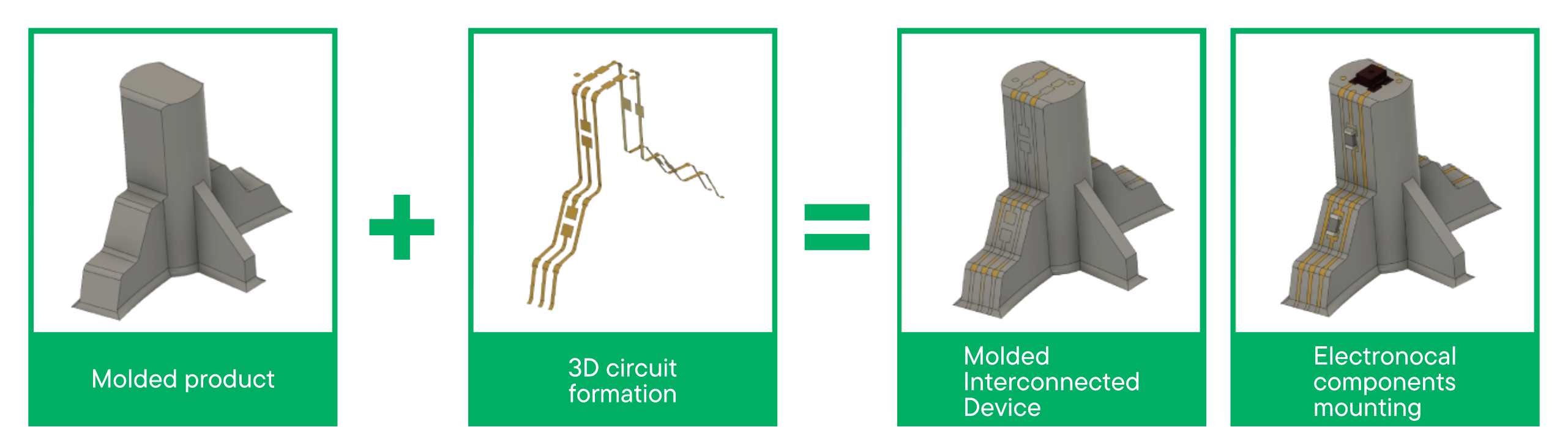

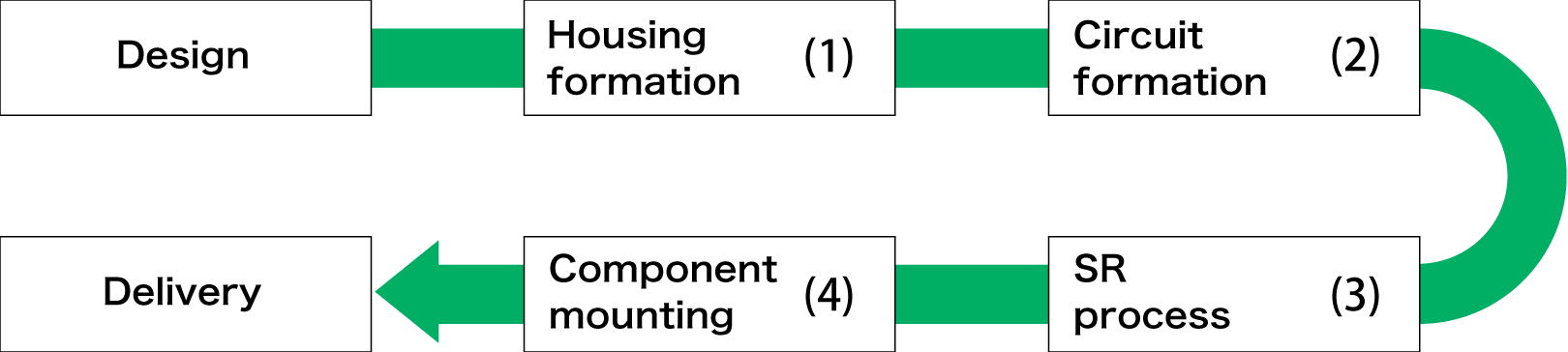

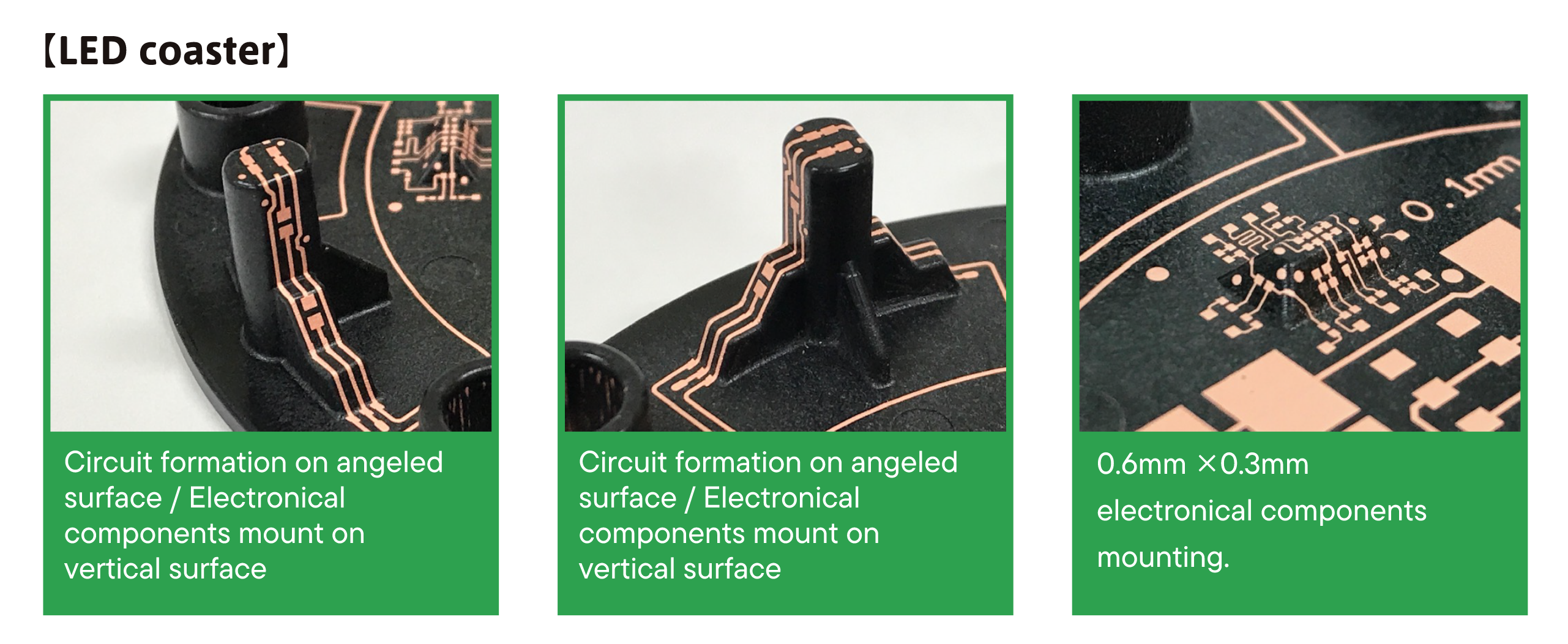

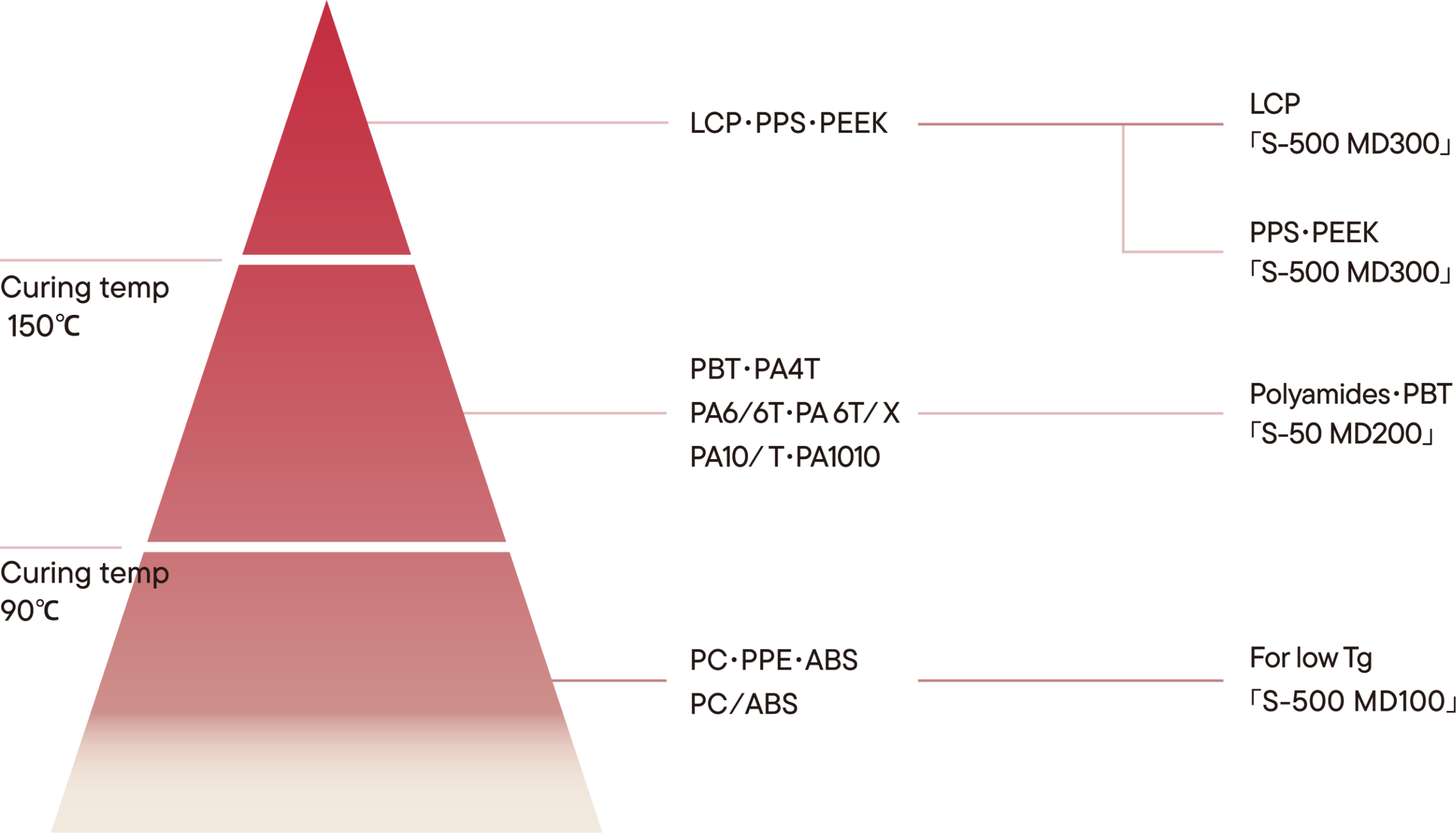

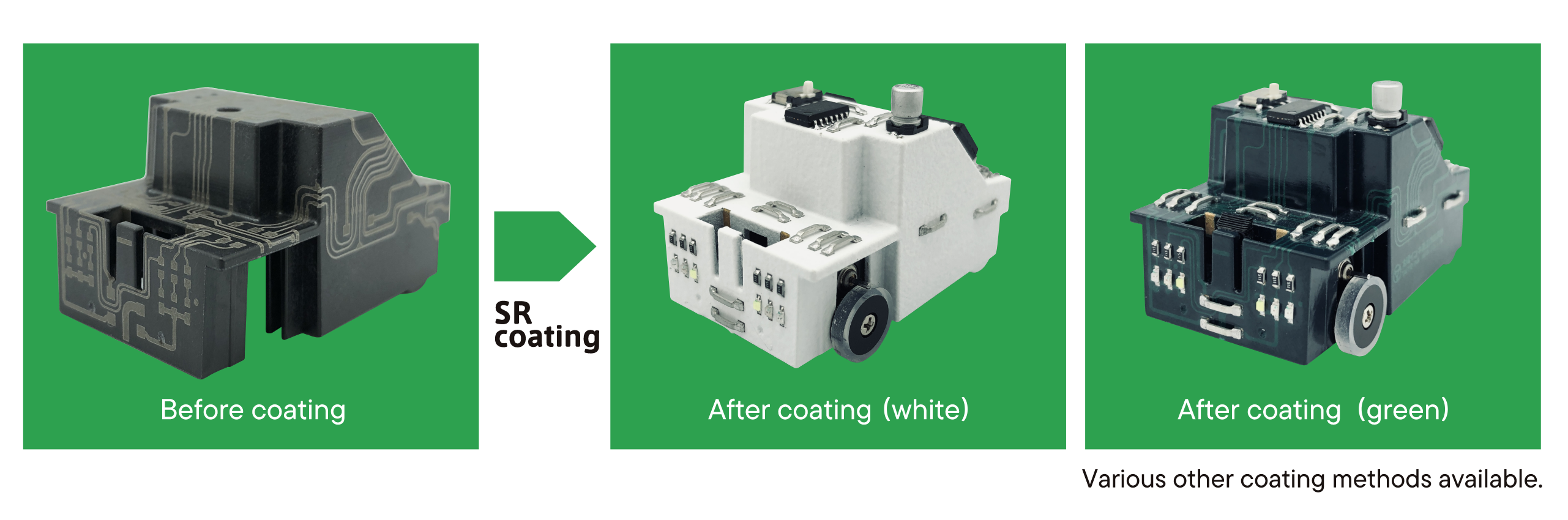

Conventionally, typical MID products such as "antenna applications" have been considered to not require solder resist.However, our SR-treated MID can realize new added value by providing a permanent protective coating on the MID substrate, i.e., protecting the circuit pattern from dust, heat, moisture, etc., and maintaining insulation.

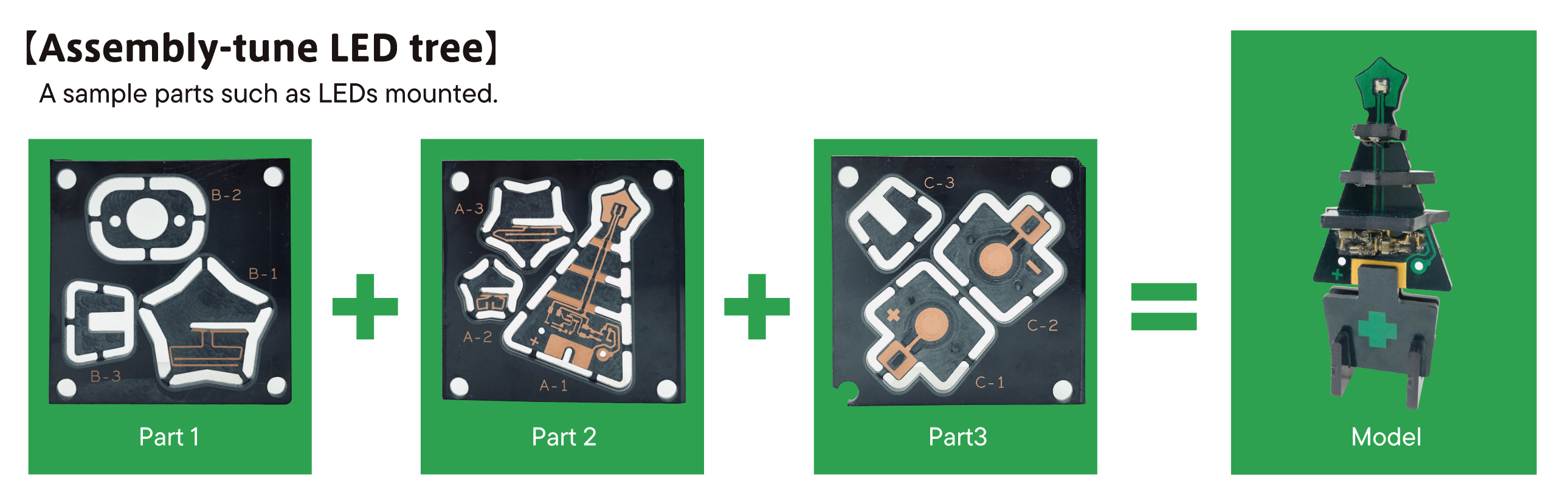

Currently, components such as antennas are fabricated only by plating, but we expect that our MID x Solder Resist will be used in the future to meet the needs of the electronics industry such as miniaturization, lightness, thinness, and shortness, which demand continues to increase every year, with value-added products that take advantage of our strength in MID x Solder Resist. We are currently undertaking many prototyping projects

We are currently undertaking many prototyping projects, and we are meeting with our customers in the development stage and conducting research in order to give them the "shape" that they envision.

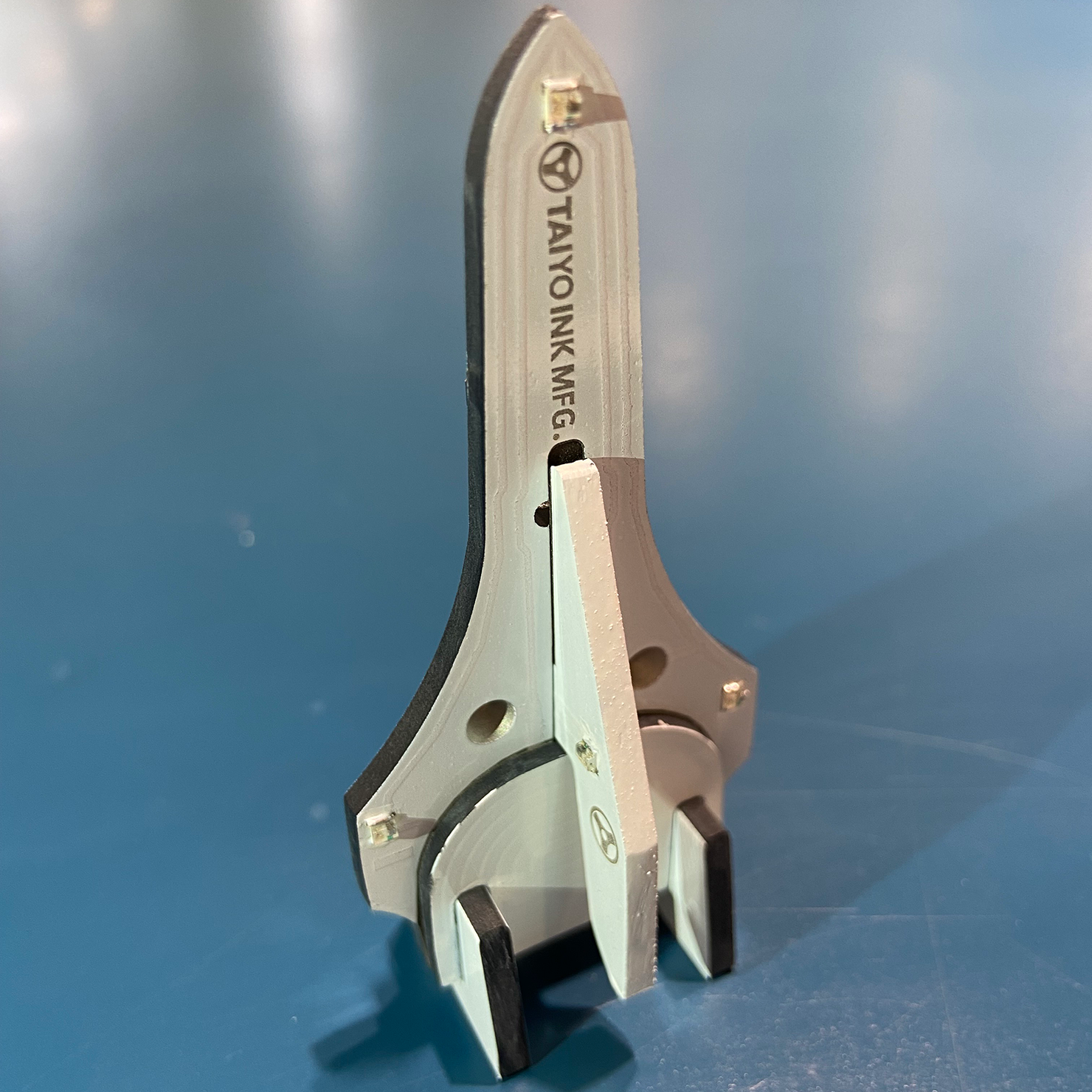

MID Rocket

(novelty)

Application

Automative / Antenna / Medical Devices / Robot / Amusement etc.